The ESR™ treated water is de-chlorinated with Hydro Optical De-Chlorination unit (HOD™), by exposure to ultra violet radiation which decomposes the oxidizer (free chlorine, chloramines, chlorine dioxide and ozone).

HOD™ Operation:

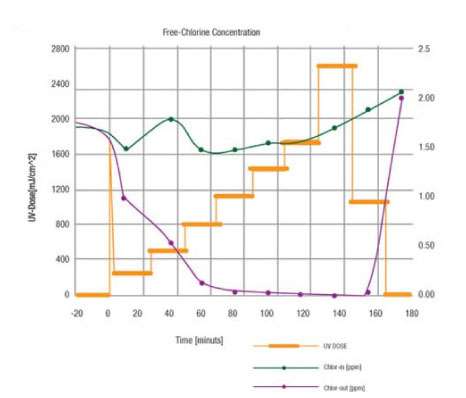

The comparison of inlet chlorine and outlet chlorine is easy with online instrumentation.

A sample graph is attached.

Chlorine levels at the HOD™ inlet are calculated for 0.5-1.0 ppm of free chlorine with exit values of less than 0.05 ppm.

HOD™ Fabrication:

The unit consists of a quartz lined radiation chamber with an SS housing and SS 316 connections.

The UV lamp is a medium pressure lamp that gives a wide spread of wave lengths.

The lamps are sized to radiate at an intensity of minimum 1700 mJ/cm2. This intensity is monitored and displayed on the control panel.

The high UV dosage breaks down the free chlorine and also disinfects the water.

As the HOD™ is modular the amount of lamps can be varied per flow rate, 1-4 lamps, can be installed.

HOD™ maintenance requirements:

The lamps and lamp gaskets have to be replaced every 4000 hours of operation.

CIP cleaning of quartz sleeve inside surface 3-4 times a year.

HOD – Chlorine

Reduction Graph

German

German English

English Brazil

Brazil