As part of its all-in-one standard comprehensive service, Biopuremax surveys the customer’s requirements, performs dimensioning and fabrication, performs FAT, on-site installation, SAT and DQ-IQ-OQ validation and documentation.

The full hot water sanitization capability gives the Biopuremax system a unique advantage: the removal of all biofilm and viable organisms through an 80°-90°C hot water cycle. Biopuremax provides Computer System Validation (CSV) as part of its standard comprehensive service.

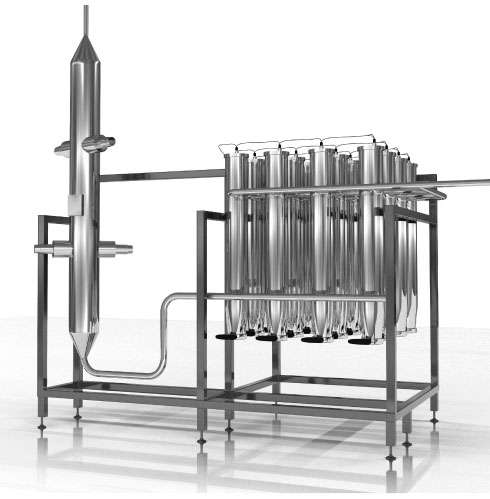

Biopuremax™ unit can be designed to fit any

water treatment system capacity

Biopuremax™ system is manufactured

according to controlled procedures after client design approval

Wet Factory Acceptance Test performed

per a pre-approved protocol

The pretreatment and

production skids are prewired and pretested so they can be quickly installed and connected to utilities

Biopuremax™ systems are supplied with full

SAT/commissioning package

Full validation package for the system

available including CSV

Biopuremax is the ultimate pure water system solution: it is an environmentally friendly, clean, simple, reliable and effective way of supplying chemical free hardness reduced water for use as RO feed water without the need of any additional treatment.

Quality & Compliance

- Validation Package

- FDA Requirements

- CGMP Requirements

- Latest USP and EP Standards

Options

- GAMP 5

- CFR 21 part 11

- Free Chlorine / Chlorine Dioxide / Ozone in City Water Tank

- Storage & Distribution Loops

- HWS for All System

- Supply of Complete System: City Water Tank, Biopuremax, RO, CEDI

German

German English

English Brazil

Brazil