ESRTM unit, also known as ESC, is composed of a Stainless Steel cylindrical reaction chamber, with a central titanium electrode. An electrical current is passed from the central anode to the cylindrical cathode so that some of the water molecules will disassociate to OH– and H+. The high concentration of OH– on the cathode will cause a high pH in the vicinity of the cathode.

High pH causes scale to precipitate and to be removed from the water and deposited on the reactor wall.

The water is not soft at the outlet of the ESRTM, but the scale forming ion content has been reduced to a level that prevents precipitation in the RO membranes.

The ESRTM will precipitate all scale forming ions, not just magnesium and calcium but also any other ions that are susceptible to dropping out of the liquid at high pH e.g. Silica, Ferum, Manganese etc.

In addition to the scale precipitation reaction, free chlorine is generated in the reactors from the feed water chloride.

The reaction is as follows:

Cl– + H+ → HCl

And then

HCl + HCl → Cl2 + H2

The Cl2 is generated in small amounts and serves to control bio-growth in the ESRTM without added chemicals.

Electrolytic Scale

Reduction-ESR™

ESRTM Operation:

The ESR operation is monitored by measuring the electrical current from the anode to the cathode. If the current is within the design range then the unit is operating correctly.

The electrical current is very safe low voltage DC.

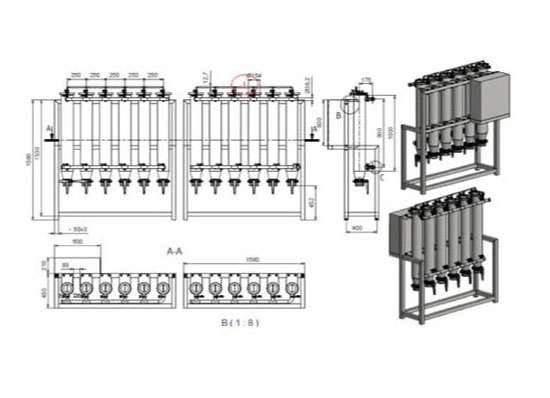

As the ESRTM is based on one standard reactor, this can be scaled to any flow rate.

The number of reactors is configured per the raw water quality, flow rate and RO configuration.

ESR Maintenance Requirements:

As scale is deposited in the reactors, the reactors have to be cleaned periodically. The cleaning frequency will vary per site conditions and a 30 second flush to drain. The period can be from twice a week to once a month. The cleaning is automatic and involves the reversal of the electrical current through the reactors.

No replacement of electrodes is needed.

German

German English

English Brazil

Brazil