Bringing Technology to Pharmaceutical Water

Biopuremax™ is a company focused on water systems in the pharmaceutical and biotech industries.

Biopuremax™ has over 20 years of experience in the design, installation, validation and operation of high quality Biopharmaceutical water systems.

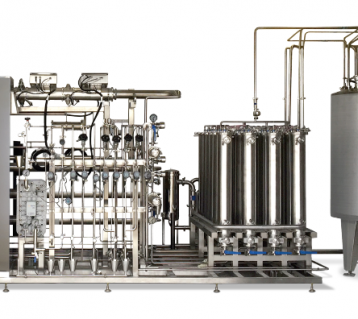

We are proud to present our demonstration skid, which will be available from the beginning of 2019 for placement in your own factory.

For more details : [email protected]

Up to 30% savings

on feed water.

Actively reduces bacteria to

very low levels before feed

to the RO.

Simple to use;

Easy to maintain;

Exceptionally reliable.

Environmentally friendly,

Completely Green

Technology.

Low operational cost,

greater efficiency.

Exceeding USP, EP and JP standards.

Biopuremax™ unit can be designed to fit

any water treatment system capacity

Biopuremax™ system is manufactured

according controlled procedures and after costumer design approval

Wet Factory Acceptance Test performed

per a pre-approved protocol

The system is based on pretreatment and

production skids that can be quickly installed and connected to utilities

Biopuremax™ systems are supplied with full

SAT/commissioning package

Full validation package for the system

available

Biopuremax Pretreatment– 1.0 m3/hr (2 gpm)

Double pass RO, PW product – 0.5 m3/hr (1.5 gpm)

Biopuremax Pretreatment and RO

Production of RO water quality – 0.5 m3/hr (2.2 gpm)

Biopuremax Pretreatment– 5.0 m3/hr (22 gpm)

Single pass RO, PW product – 3 m3/hr (13 gpm)

Biopuremax Pretreatment– 9.5 m3/hr

Double pass RO/CDI, PW product – 4.5 m3/hr

Thermo Compression Distillation Unit – 3 m3/hr

WFI Storage and distribution systems – 30 m3

Biopuremax Pretreatment– 4 m3/hr

Single pass RO/CDI, PW product – 0.6 m3/hr

Single pass RO/CDI, PW product – 0.6 m3/hr

WFI Storage and distribution systems – 3 m3

Biopuremax Pretreatment– 4 m3/hr

Single pass RO/CEDI, PW product – 0.6 m3/hr

PW Storage and distribution systems – 2 m3

Hot PW distribution loops – Central cooling

Biopuremax Pretreatment – 1.0 m3/hr

Single pass RO, PW product – 0.5 m3/hr

Pretreatment multimedia and softeners – 25 m3/hr

Single stage RO/CEDI, Hot water sanitizable – 4 m3/hr

Six stage multi effect Distillation Unit – 1.6 m3/hr

WFI Storage systems – 20 m3

Biopuremax Pretreatment– 1.0 m3/hr (2 gpm)

Double pass RO, WFI product – 0.5 m3/hr (1.5 gpm)

German

German English

English Brazil

Brazil